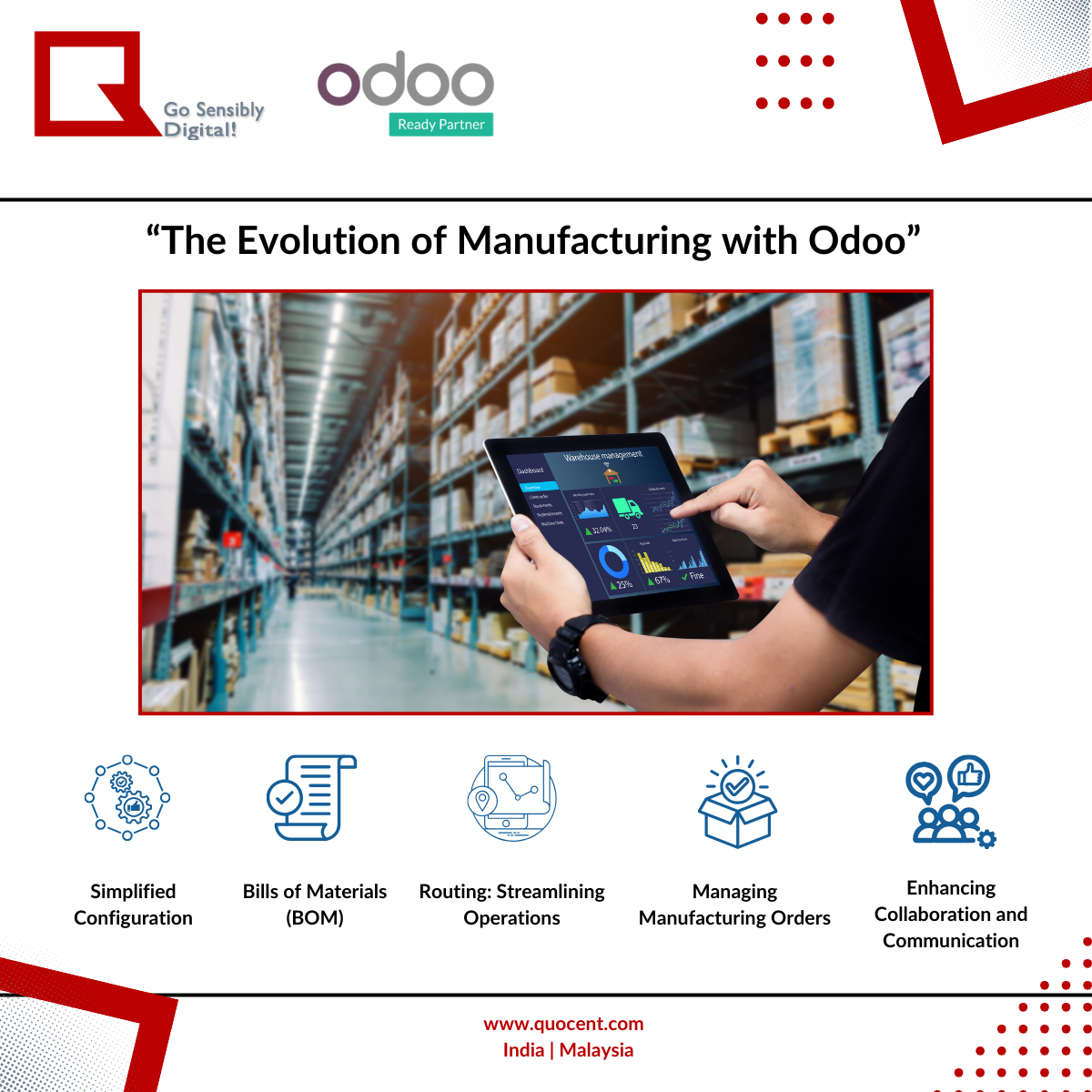

Ah, the manufacturing industry—where machines hum, assembly lines buzz, and chaos reigns supreme. Enter Odoo Manufacturing—a powerful software solution designed to streamline your production processes and enhance overall productivity. With its comprehensive features and user-friendly interface, Odoo can transform how your manufacturing business operates. Let’s dive into how Odoo helps the manufacturing industry thrive.

It offers simplified Configuration

Setting up Odoo’s Manufacturing module is a straightforward process. Once installed, you gain access to a wealth of features that can be tailored to your specific needs. The first step is to establish your work centres, where the real action happens.

Work Centers: The Heart of Production

Work centres are critical to managing your manufacturing operations. In Odoo, you can create detailed profiles for each work centre, specifying performance metrics such as capacity, efficiency, and cost per hour. This level of granularity allows you to optimise resources effectively, ensuring that each centre operates at peak performance.

Bills of Materials (BOM): Your Recipe for Success

The Bill of Materials (BOM) is a foundational component in manufacturing. It lists all the raw materials, components, and subassemblies needed to produce a finished product. In Odoo, you can easily define and manage BOMs, making it simple to track inventory requirements and reduce the risk of shortages. This not only enhances planning but also helps maintain quality control across your production line.

Routing: Streamlining Operations

Routing in Odoo outlines the specific sequence of operations required to produce a product. This feature allows you to map out the manufacturing process across different work centres, detailing each step and the associated timeframes. By creating clear routing paths, you can identify bottlenecks and optimise workflows, resulting in smoother operations and quicker turnaround times.

Managing Manufacturing Orders

Once your configurations are in place, you’ll dive into managing manufacturing orders. Odoo allows you to generate these orders automatically based on stock levels, ensuring that you never run out of essential materials. This automation reduces manual intervention and minimises errors, allowing your team to focus on more strategic tasks.

Make to Order: Flexibility at Its Best

For businesses that operate with minimal inventory, the “Make to Order” feature is invaluable. This functionality ensures that production begins only when an order is placed, reducing excess stock and associated carrying costs. It’s an excellent strategy for businesses aiming to be lean and responsive to customer demands.

Enhancing Collaboration and Communication

Odoo also promotes collaboration across departments. With integrated tools for sales, inventory, and customer relationship management (CRM), your team can easily share information. This holistic approach allows for better decision-making and a more coordinated response to market changes.

Conclusion: Embrace Odoo for Manufacturing Success

At Quocent, we offer Odoo Manufacturing, a robust solution for businesses looking to enhance efficiency and streamline their operations. From configuring work centres and BOMs to managing manufacturing orders and routing, Odoo provides the tools necessary to navigate the complexities of production.

As the manufacturing industry continues to evolve, leveraging software like Odoo can give your business a competitive edge. Embrace the capabilities of Odoo, and watch as it transforms your manufacturing processes into a well-oiled machine, ready to meet the demands of today’s market.